New Microscope Unlocks Hidden Atomic Architecture in Advanced Materials

Researchers at the University of Sydney have developed a new microscopy method that uses atom probe tomography to observe atomic-scale changes in materials. This advancement enhances understanding of materials properties and could lead to stronger alloys for aerospace, more efficient semiconductors, and better magnets for motors.

Researchers at the University of Sydney have developed a new microscopy method using atom probe tomography to explore atomic-level changes in materials, promising significant advances in materials science and engineering.

A new microscopy technique enables researchers to observe minute changes in the atomic structure of crystalline materials, such as advanced steels used in shipbuilding and custom silicon for electronics. This method has the potential to enhance our understanding of the fundamental origins of material properties and behavior.

In a paper published in Nature Materials, researchers from the University of Sydney’s School of Aerospace, Mechanical, and Mechatronic Engineering introduced a new way to decode the atomic relationships within materials.

The breakthrough could assist in the development of stronger and lighter alloys for the aerospace industry, new-generation semiconductors for electronics, and improved magnets for electric motors. It could also enable the creation of sustainable, efficient, and cost-effective products.

Advanced Techniques in Atom Probe Tomography

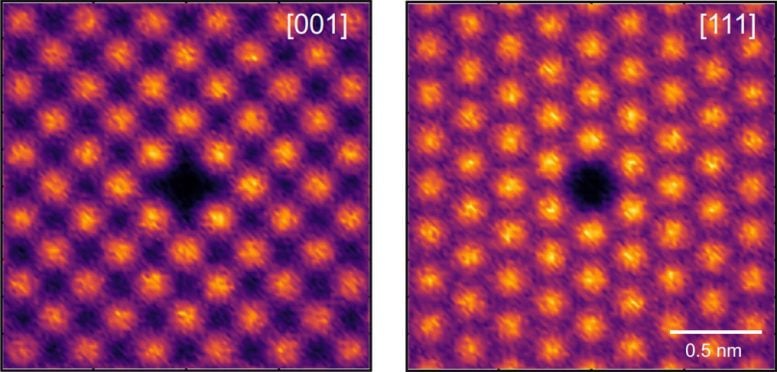

The study, led by University of Sydney Pro-Vice-Chancellor (Research Infrastructure) Professor Simon Ringer, harnessed the power of atom probe tomography (APT) to unlock the intricacies of short-range order (SRO). The SRO process is key to understanding the local atomic environments essential for the development of innovative materials that could underpin a new generation of alloys and semiconductors.

SRO is sometimes likened to the ‘materials genome’, the arrangement or configuration of atoms within a crystal. This is significant because different local atomic arrangements influence the electronic, magnetic, mechanical, optical, and other properties of materials, which have a bearing on the safety and functionality of a range of products.

Until now, SRO has been challenging for researchers to measure and quantify because atomic arrangements occur at a scale so small that they are difficult to see with conventional microscopy techniques.

The new method using APT, developed by Professor Ringer’s team, overcomes these challenges, paving the way for advances in materials science that could have far-reaching implications across steels for ship hulls and custom silicon for electronics in a range of industries.

“Our research presents a significant breakthrough in materials science,” said Professor Ringer, a materials engineer in the School of Aerospace, Mechanical and Mechatronic Engineering (AMME).

“Beyond crystal structure and symmetry, we wanted to know more about the atomic-scale neighborhood relationships within the crystal—are they random, or non-random? If the latter, we want to quantify that. SRO gives us this information in detail, opening up vast possibilities for materials that are custom-designed, atom-by-atom, with specific neighborhood arrangements to achieve desired properties like strength.”

The study focused on high entropy alloys, which are promising for various advanced engineering applications.

Implications and Future Research

“These alloys are the subject of an enormous worldwide research effort because of the interest in using them in situations requiring high-temperature strength, such as in jet engines and power plants, as well as for neutron irradiation shielding in nuclear reactors, where protection against radiation damage is necessary,” said Professor Ringer.

The team used advanced data science techniques drawing on data from APT —a sophisticated imaging technique that visualizes atoms in 3D, allowing the team to observe and measure SRO, comparing how it changes in alloys under different processing conditions.

The research focused on observations of a cobalt-chromium-nickel high entropy alloy, revealing how different heat treatments can change SRO.

“This provides a template for future studies in which SRO controls critical material properties. There is lots more to do on various aspects of the analysis of SRO—it’s a hard problem, but this is an important step forward,” said Professor Ringer.

Dr Mengwei He, postdoctoral research fellow in the School of Aerospace, Mechanical, and Mechatronic Engineering said:

“The ability to measure and understand short-range order has transformed our approach to materials design. It gives us a new set of eyes to see how small changes at the atomic level architecture can lead to giant leaps in materials performance.”

Critically, the study enhances the capabilities of researchers to computationally simulate, model and ultimately predict materials behavior because SRO provides a detailed atomic-scale blueprint.

Senior postdoctoral fellow Dr Andrew Breen said: “We have demonstrated that there are regimes where the SRO really can be measured using atom probe tomography. Not only have we pioneered an experimental approach and computational framework to measuring SRO, we have produced a sensitivity analysis that bounds the precise range of circumstances whereby such measurements are valid, and where they are not valid.”

Dr Will Davids, who completed his doctorate with Professor Ringer and now works for engineering firm Infravue said: “This is an exciting advance because we’ve shown that SRO measurements are possible in multicomponent alloys, which will no doubt be of benefit to the materials science and engineering community. The community is now going to want to learn how to further expand the measurable regime of SRO, so a big space in this research field has just opened up.”

Reference: “Quantifying short-range order using atom probe tomography” by Mengwei He, William J. Davids, Andrew J. Breen and Simon P. Ringer, 2 July 2024, Nature Materials.

DOI: 10.1038/s41563-024-01912-1

The research was supported by the Australia Research Council’s (ARC) Discovery Program. The team also acknowledges support from the Australia–US Multidisciplinary University Research Initiative (AUSMURI) program supported by the Australian Government. The team acknowledges technical and scientific support for experiments conducted at the following research facilities: Sydney Microscopy and Microanalysis (SMM), Sydney Analytical, Sydney Informatics Hub, and Sydney Manufacturing Hub. SMM is a foundational node of Microscopy Australia, the NCRIS-supported national microscopy facility. This research team are all members of the School of Aerospace, Mechanical, and Mechatronic Engineering in the Faculty of Engineering, and are members of the Australian Centre for Microscopy & Microanalysis. A patent application by Professor Ringer is partly related to this work.