How Zero Gravity Could Make Your Beer Taste Better

A study by the University of Florida found that beer yeast ferments faster but produces fewer flavoring esters in simulated microgravity, hinting at better-quality beer production in space.

New insight into how beer yeast might behave when fermented in outer space is provided in a recently published study.

While the concept may initially sound trivial, it has far-reaching applications, according to the study, a collaboration between researchers from the University of Florida, Institute of Food and Agricultural Sciences (UF/IFAS) food science and human nutrition department and the horticultural sciences department.

Fermentation is an essential process in the creation of food products including bread, yogurt and kombucha. Biofuels and many pharmaceuticals are also generated through fermentation. But the researchers chose to analyze beer yeast fermentation because humans have brewed beer for thousands of years, and there is an established foundation of knowledge about it.

“We are absolutely going to be conducting fermentations under microgravity in the future, as we continue space exploration, and there are going to be outcomes that will be very difficult for us to predict,” said study author Andrew MacIntosh, a UF/IFAS associate professor of food science. “It’s essential that we look at what some of those outcomes may be, now, so we can decide which processes are going to be the first ones we perform under microgravity, how we adapt them, and how we can take advantage of the changes we see.”

Experiment Setup and Microgravity Simulation

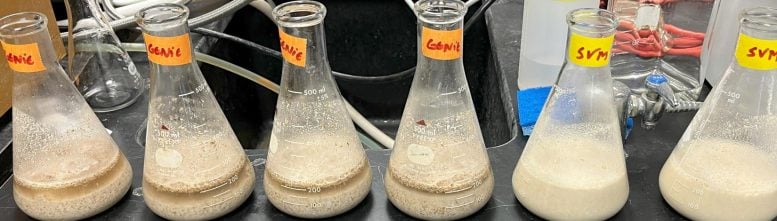

Pedro Fernandez Mendoza led the study as an undergraduate researcher. His team took barley grown in Live Oak, Florida, and mashed it to create wort, a liquid solution of extracted grains. They divided the wort into six identical samples and initiated fermentation by combining the samples in tubes with Saccharomyces pastorianus, the species of beer yeast used for brewing lagers.

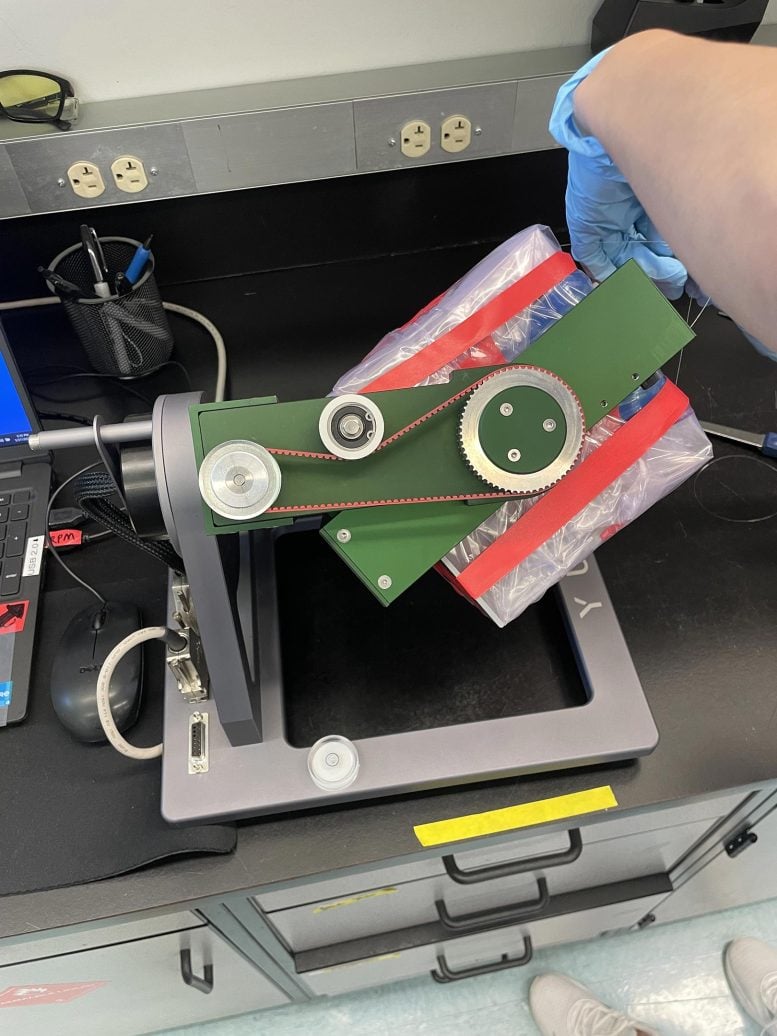

Three tubes acted as controls, and three tubes were placed inside a clinostat, a device that simulates microgravity by rotating samples around a horizontal axis.

Results of Fermentation in Simulated Microgravity

As the researchers hypothesized, microgravity did not adversely affect the number of yeast cells or their viability. Instead, the rate of fermentation increased. They attributed this result to the cells’ constant suspension, a state that maximized nutrient availability by preventing settling.

Surprisingly, however, the yeast exposed to microgravity produced fewer esters, the byproducts of fermentation that create both desirable and undesirable beer flavors. While suspension could be responsible, the researchers learned a yeast gene that regulates ester production might also play a part; the gene was expressed less in yeast samples exposed to microgravity than in control samples.

Conclusions and Future Research

The researchers concluded the ester levels observed in the microgravity samples would likely lead to the creation of a higher-quality product compared to those observed in the control samples.

MacIntosh said the team’s research marks only the beginning of understanding how microgravity can be leveraged to improve products used every day.

“This study is definitely the first piece in the puzzle, and I’m excited to do more,” he said.

Reference: “Brewing Beer in Microgravity: The Effect on Rate, Yeast, and Volatile Compounds” by Pedro Fernandez Mendoza, Katherine A. Thompson-Witrick, Skylar R. Moreno, Santiago Cárdenas-Pinto, Zhen Jia, Lincoln Zotarelli, Boce Zhang and Andrew J. MacIntosh, 18 June 2024, Beverages.

DOI: 10.3390/beverages10020047

Source link