3D-Printed Artificial Blood Vessels Could Revolutionize the Treatment of Heart Disease

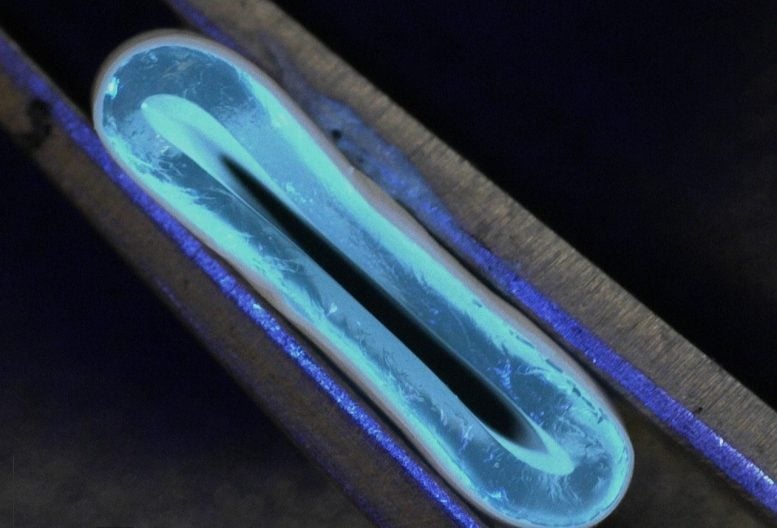

Innovative 3D-printed vascular grafts developed by the University of Edinburgh show the potential to revolutionize heart bypass surgeries, combining strength, flexibility, and reduced complication risks in a novel medical application. Credit: Dr Norbert Radasci, School of Engineering, University of Edinburgh.

3D-printed blood vessels that closely resemble the properties of human veins could revolutionize the treatment of cardiovascular diseases.

Experts say that newly developed strong, flexible, gel-like tubes, created through an innovative 3D printing technology, have the potential to enhance outcomes for heart bypass patients by replacing the human and synthetic veins currently used in surgery to re-route blood flow.

The development of synthetic vessels could help limit scarring, pain, and infection risk associated with the removal of human veins in bypass operations of which some 20,000 are carried out in England each year. The products could also help alleviate the failure of small synthetic grafts, which can be hard to integrate into the body.

In a two-stage process, a team of researchers led by the University of Edinburgh’s School of Engineering used a rotating spindle integrated into a 3D printer to print tubular grafts made from a water-based gel.

They subsequently reinforced the printed graft in a process known as electrospinning, which uses high voltage to draw out very thin nanofibers, coating the artificial blood vessel in biodegradable polyester molecules. Tests showed the resulting products to be as strong as natural blood vessels.

Versatility and Future Research Directions

The 3D graft can be made in thicknesses from 1 to 40 mm in diameter, for a range of applications, and its flexibility means that it could easily be integrated into the human body, the team says. The next stage of the study will involve researching the use of the blood vessels in animals, in collaboration with the University of Edinburgh’s Roslin Institute, followed by trials in humans.

The research, published in Advanced Materials Technologies, was carried out in collaboration with Heriot-Watt University.

Dr Faraz Fazal, of the University of Edinburgh’s School of Engineering and lead author, said: “Our hybrid technique opens up new and exciting possibilities for the fabrication of tubular constructs in tissue engineering.”

Dr. Norbert Radacsi, of the University of Edinburgh’s School of Engineering and principal investigator, said: “The results from our research address a long-standing challenge in the field of vascular tissue engineering – to produce a conduit that has similar biomechanical properties to that of human veins.

“With continued support and collaboration, the vision of improved treatment options for patients with cardiovascular disease could become a reality.”

Reference: “Fabrication of a Compliant Vascular Graft Using Extrusion Printing and Electrospinning Technique” by Faraz Fazal, Ferry P.W. Melchels, Andrew McCormack, Andreia F. Silva, Ella-Louise Handley, Nurul Ain Mazlan, Anthony Callanan, Vasileios Koutsos and Norbert Radacsi, 25 July 2024, Advanced Materials Technologies.

DOI: 10.1002/admt.202400224